Range of Application

United Kingdom

Sytner BMW

Surface: 4000 m2

Volume: 16000 m3

Kind of hall: 3 No. RPVE 2096 in direct gas-fired warm air heaters, each fitted with 2-stage DX cooling coil.

Total installed capacity: Type of installed heaters: 17 x Euro-T2000A ceiling mounted warm air heaters. Room sealed units with automatic hot surface ignition, avoiding the need for continuous pilot lights.

Manufacturer: Reznor

Description of the project: Having a new state of the art Showroom, it was only appropriate to have a high efficient heating system to provide constant customer comfort within Syter BMW’s new building.

Reznor rose to the challenge, providing them with Warm Air Heaters that maintained a consistent 20-21 degrees temperature.

Sytner BMW is one of the UK’s larger car dealer networks. It outgrew its existing city centre showroom in Nottingham, and relocated to an out-of-town site. The new showroom is a flagship for the company, with around 4,000m² of floor space – enough to accommodate all the models from the BMW range together with a used car area and a new Mini showroom.

To ensure air temperatures within the showroom provide constant comfort conditions for customers and staff, Sytner sought a high efficiency solution to the heating needs of its new state of the art building.

Reznor indirect fired warm air units were installed to maintain even comfort temperatures in the showroom. The units are fully modulating and fitted with two-stage DX cooling coils.

Tempered air is brought into the showroom via ducting and distributed throughout the interior by means of drum diffusers positioned at ceiling level, approximately five metres from the floor.

In the workshop, where external doors open and close frequently to allow cars in and out, Ambi-Rad radiant tube heaters were installed. Radiant tube heating works like the sun, heating only people and objects in its path. The Ambi-Rad heaters take the chill off machinery and ensure people feel warm within minutes of start-up, or after a period when the door is open. However, no energy is wasted in heating the volume of air in the building, making it an extremely economical solution in a workshop environment.

A consistent 20-21 degrees is maintained in the showroom during cold weather, ensuring a pleasant internal environment for customers and staff. Fully modulating burners mean the system operates at optimum efficiency since nearly all fuel consumed is turned into usable heat. DX coiling coils are used to create a fresher environment in the showroom during hot spells.

The tempered air is brought into the showroom via ducting and distributed throughout the interior by means of drum diffusers positioned at ceiling level, approximately five metres from the floor.

In the workshop, where external doors open and close frequently to allow cars in and out, Ambi-Rad radiant tube heaters were installed. Radiant tube heating works like the sun, heating only people and objects in its path. The Ambi-Rad heaters take the chill off machinery and ensure people feel warm within minutes of start-up, or after a period when the door is open. However, no energy is wasted in heating the volume of air in the building, making it an extremely economical solution in a workshop environment.

East Midlands Airport

Surface: 5600 m2

Volume: 112000 m3

Required room temperature: 20°C

Type of installed heaters: Free standing oil fired heaters

Manufacturer: Reznor

Description of the project: Bibby & Barron manufactures paper bags for most of the UK’s blue chip retail operations.

Application: A total of 17 Reznor Eurot-T2000A ceiling mounted warm air heaters were installed at 4 meters roof height throughout the premises. The room-sealed units were equipped with automatic hot surface ignition, avoiding the need for continuous pilot lights, and flued to atmosphere through the roof. The use of ducted external air for combustion eliminated contamination from the fumes inside the factory. This prevents them being introduced into the combustion process. High-low burner control provides optimum levels of operating efficiency, thereby maximising energy usage. The use of high air-flow units meant no destratification fans were required since the heaters both move internal air effectively and recirculate via secondary air entrainment. The units were also fitted with high grade 316 stainless steel heat exchangers which are resistant to corrosion from harmful chemicals.

Benefits: Three months after installation, Bibby & Barron estimated their energy savings over the cost of running the old boiler system to be in the region of 50 percent. With high efficiency but low running and maintenance costs, the company anticipates payback on its capital investment within only one year. The system is proving a flexible solution to Bibby Barron’s heating needs in its factory. As well as being easy to control and maintain, the system provides year-round constant comfort conditions within the production area.

Norwich union

Surface: 4287 m2

Volume: 25722 m3

Kind of hall: Storage space

Required room temperature: 21 °C

Type of installed heaters: 11 x C4074 (46kW) compact warm air units, wall-mounted 5 x Euro T2236 at mezzanine floor level

Extra installed air recirculation:

Special features: 20 x Maximisor destratification fans

Manufacturer: Reznor

Description of the project: John Shannon of Roberts & Partners comments: „The system effectively achieves total heat distribution around the racking and working areas of the building. Reznor warm air units are renowned for good quality and longevity – I had no hesitation in specifying them for this application.“

Norwich Union, the UK’s largest insurance group, extended its storage capability with the acquisition of a new facility in Norwich. The building required a completely new heating system to ensure a comfortable working environment for employees could be maintained at all times.

As Norwich Union’s main storage facility, the premises contain floor-to-ceiling racking, with aisles to allow fork-lift retrieval of documents.

Ensuring even distribution of heat around the building, with its racking, mezzanine floor and high bays, was a key criterion of the heating systems.

Eleven Reznor C4074 compact warm air unit heaters were wall-mounted between the racks, just below roof level. Strategic positioning of the heaters around the perimeter of the building ensure warm air discharges directly down aisles between racks. The warm air is redistributed throughout the main storage and high bay areas by 20 roof-mounted Maximizor recirculation fans.

In addition, a ducted warm air system powered by five Euro T2236 units was installed at mezzanine floor level.

Despite the considerable challenges posed by the interior architecture, the Reznor heating system maintains a constant 21°C throughout the building, thanks to the correct positioning of heaters and the addition of a ducted system to the mezzanine floor. Employees feel comfortable wherever they are working within the premises.

The Reznor system was recommended by Roberts & Partners of Glasgow, retained consultants for Norwich Union, as they believe Reznor to be renowned for their high quality systems, and was then installed by M & E contractor ABB Building Technologies Ltd of Ipswich.

Norwich union

Surface: 1560 m2

Volume: 9380 m3

Kind of hall: Sport

Type of installed heaters: 3 No. T2000E gas-fired warm air heaters

Manufacturer: Reznor

Description of the project:

The primary requirement of the heating system needed at new Beaconside Campus Sports Complex was to maintain comfort levels with good heat coverage. Reznor installed three Warm Air Heaters to successfully achieve comfort temperatures in all areas of activity using air mixing ducts to provide heat without air turbulence.

The new Beaconside Campus Sports Complex in Stoke-on-Trent is Staffordshire University’s flagship sporting facility. Built in 2000, the premises comprise a 620m² sports hall, 220m² ancillary hall, 270m² fitness suite and changing and shower areas. The facility is in constant use by students, recreational groups and the general public for a variety of sporting activities, from basketball and football, to dance and martial arts.

The primary requirement of the heating system was to effectively maintain comfort temperatures in all areas of the complex, regardless of the level of activity taking place within. Heat coverage had to be uniform throughout, and achieved without air movement or draughts.

Three Reznor T2000E gas-fired warm air heaters were installed in a first floor plant rooms to serve the main hall, ancillary hall and changing area. A Reznor electrically heated unit serves the Fitness Suite, and is located in an adjacent plant room.

Reznor Air Mixing air distribution ducts were also fitted in the main hall, ancillary hall and Fitness Suite to provide the required level of heat diffusion, but without air turbulence. The PVC Air Mixing ducts, which are suspended from the ceiling, are perforated along their length. Air is forced through at high speed to produce an immediate mix with room air, thereby eliminating the problem of condensation on cold surfaces and providing evenly distributed warm air. An Energymizor control panel in each room enables sports hall staff to adjust local temperatures according to internal conditions, and to monitor and override the system when required.

The Reznor heating solution answers the requirements of the University for a system that economically overcomes both fabric and ventilation losses. The high level distribution allowed by Air Mixing ducts is both unobtrusive and avoids the use of low level emitters which could interfere with sporting activities.

The choice of indirect gas-fired warm air heaters enabled the University to minimise boiler plant and low pressure hot water pipe work distribution. At the same time, the Air Mixing ducts offer an aesthetically pleasing solution that avoids grilles and diffusers. Their excellent air distribution qualities ensure air velocities within all areas of sports play are maintained at an acceptable level.

Economical running is optimised by the use of timed operation,set-back warm-up and damper settings.

Unipart

Surface: 93000 m2

Volume: 837000 m3

Required room temperature: °C

Total installed capacity: kW

Type of installed heaters: 105 No. Reznor XD400 and XB400 gas-fired warm air heaters – 220 No. Maximizor – recirculation fans – 14 No. air curtains

Manufacturer: Reznor

Description of the project: Ron Mansfield of Unipart oversaw the project. He comments: “From my calculations I was doubtful whether we would achieve the two year payback period required. What the system actually achieved was remarkable, having now paid for itself many times over.“

“Our employees noticed the difference immediately. Operation and maintenance of the system are simple and we have a constant working temperature that is comfortable for everyone.”

Unipart DCM, one of Europe’s leading providers of out sourced aftermarket logistics and distribution services, has occupied its Cowley premises since 1964. At 93,000m², it is the biggest of four Unipart DCM distribution centres in the UK.

Originally, the building was equipped with a high pressure hot water heating system which ran off three very large boilers. Heat was supplied to operational areas via radiant strip heat emitters, positioned at 9 metres in the roof. With 250 tonnes of water circulating round the heating pipes, the system would take up to three days to warm up to a comfortable temperature. High running and maintenance costs made the system increasingly uneconomic.

Planning to decentralise the system, Unipart sought a highly economic and efficient alternative. The company also stipulated a two-year minimum payback period for any system they chose.

A Reznor warm air heating system consisting of 105 unit heaters, including the XD400, XAA400 and XB400 models, was installed. The heaters were positioned both around the building in four discrete zones, and adjacent to loading bay doors.

A further 14 air curtains were fitted over the loading bay doors, while in the roof, a total of 220 Maximizor recirculation fans were installed. These re-distribute risen warm air from high level down to lower, operational levels.

The benefits of the Reznor system were apparent immediately, when employees noticed a warmer environment within thebuilding. Unipart is now able to maintain a constant working temperature that is comfortable for everyone, with rapid heat up even on very cold mornings.

The complementary operation of heaters, recirculation fans and over door air curtains (which effectively prevent cold air from entering through external doors that are constantly in use) meant running efficiencies were also gained quickly. As a result, the payback period was achieved in just nine months, beating the two-year deadline by 15 months.

On-going energy savings since the system was installed have been running at around 35 per cent a year, and the company continues to save, the system having now paid for itself many times over.

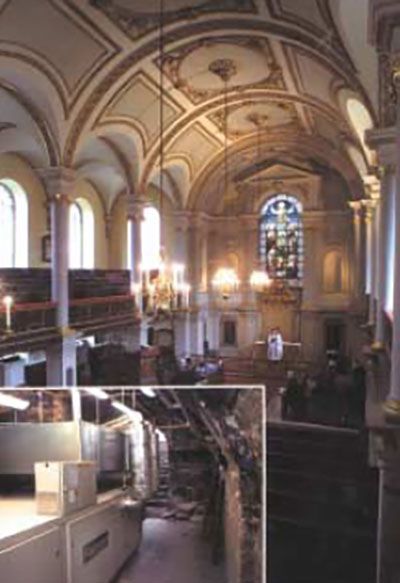

St. Giles Church

Kind of hall: Church

Required room temperature: 18 °C

Type of installed heaters: 1 Reznor EuroPak PV 2095-20 gas-fired warm air heater, engineered to the requirements of the application. Fitted with supply air fan, optional filter section and modulating burners

Manufacturer: Reznor

Description of the project: There has been a house of prayer on the site of St Giles in the Field Church in Bloomsbury since 1101, when St Giles was a small village outside London. The existing Palladian-style church was designed and built in the early 1730s by Henry Flitcroft, who also worked on Woburn Abbey. The 30-year old warm air heating system had broken down and was beyond repair. A replacement system would have to satisfy the particular requirements of the historic church – namely, to make use of existing underfloor ductwork, to warm the church quickly and effectively at very low noise levels, and to be highly energy efficient. Most importantly, installation of the system should not interfere with or alter in any way the integrity of the building’s existing framework.

Application: Since the only available space to install a warm air system capable of meeting all the specific requirements of the building was in the church basement with extremely restricted access, a flexible tailor-made solution was required. Reznor supplied a EuroPak PV 2095-20 gas-fired warm air heater, complete with supply air fan, optional filter section and modulating burners to allow enhanced temperature control. From its basement location, the heater could be easily linked to the existing distribution system within the church. Access to the basement was very restricted, so the heating system was supplied in sections and re-assembled on site.

Bibby & Barron

Volume: 25600 m3

Kind of hall: Manufactoring paper bags

Type of installed heaters: 17 x Euro-T2000A ceiling mounted warm air heaters. Room sealed units with automatic hot surface ignition, avoiding the need for continuous pilot lights.

Manufacturer: Reznor

Description of the project: Bibby & Barron manufactures paper bags for most of the UK’s blue chip retail operations.

Application: A total of 17 Reznor Eurot-T2000A ceiling mounted warm air heaters were installed at 4 meters roof height throughout the premises. The room-sealed units were equipped with automatic hot surface ignition, avoiding the need for continuous pilot lights, and flued to atmosphere through the roof. The use of ducted external air for combustion eliminated contamination from the fumes inside the factory. This prevents them being introduced into the combustion process. High-low burner control provides optimum levels of operating efficiency, thereby maximising energy usage. The use of high air-flow units meant no destratification fans were required since the heaters both move internal air effectively and recirculate via secondary air entrainment. The units were also fitted with high grade 316 stainless steel heat exchangers which are resistant to corrosion from harmful chemicals.

Benefits: Three months after installation, Bibby & Barron estimated their energy savings over the cost of running the old boiler system to be in the region of 50 percent. With high efficiency but low running and maintenance costs, the company anticipates payback on its capital investment within only one year. The system is proving a flexible solution to Bibby Barron’s heating needs in its factory. As well as being easy to control and maintain, the system provides year-round constant comfort conditions within the production area.

Courts

Surface: 2600 m2

Volume: 3380 m3

Kind of hall: stores

Type of installed heaters: H30067B: warm air condensing unit heater

Manufacturer: Reznor

Description of the project: Courts is one of the UK’s leading home furnishing retailers. It has over 30 out-of-town stores across the country.

Application: In line with Courts‘ energy efficiency criteria, Reznor ceiling-mounted warm air condensing heaters have been installed in over 30 of the company’s out-of-town sores and are scheduled to be fitted in all new-build ’shed‘ stores. The condensing unit heaters have an operating efficiency of 92 per cent which is 10 per cent more than other warm air heaters. The condensing technology utilises an additional heat exchanger which extracts heat from the products of combustion before they are expelled into the atmosphere. The extracted heat pre-heats the air before it passes across the main heat exchanger, reducing energy usage as a result.

Instron Limited

Surface: 7500 m2

Volume: 37500 m3

Kind of hall: Instron Limited of High Wycombe manufactures precision instruments and systems for testing materials and products used in a broad cross-section of industries

Type of installed heaters:

9 x T2000E warm air heating/ventilating units in four zones

Manufacturer: Reznor

Application: The requirement for both ventilation and heating across four different zones indicated that a warm air system would be the most appropriate solution. Nine T2000E Reznor units with 316 grade stainless steel heat exchangers were installed to heat 7,500m2 of the factory floor. On start-up and during cold weather, the heaters work on total recirculation of air. In summer, dampers can be automatically switched to recirculation and fresh air, or total fresh air. The system is controlled from a PC terminal using a software programme specially designed by TA Controls. Tamper-proof localised sensing points detect ambient temperature in each zone. The heating system, or individual units, can be viewed graphically on screen, and controls amended by a simple point and click operation. The management system also detects faults, isolates them and re-sets where the fault is not complex.

Benefits: Instron saved 35 per cent on heating bills in the first year after installation. The Reznor system is proving responsive, efficient and easy to operate.